Building single coil guitar pickups; Hybrids part 2

The first part of the building single coil guitar pickups blog focussed on initial checking and preparation of the pickups. That included hand setting the distinctive Hybrid pole piece stagger pattern.

So now the pickups are ready for wax potting in a wax bath.

Wax potting is simply the immersion of pickups in hot, liquefied wax. Because the liquid wax penetrates into the wound coil, it drives out small air pockets. When the pickup cools, the wax 'solidifies' and thus binds all of the coil mechanically. This then stops the individual windings vibrating which causes the phenomena of microphonic feedback (squealing).

Additionally, the pole pieces which were manually set are 'glued' in place by the waxing process.

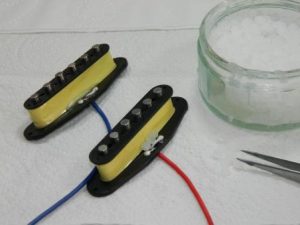

Wax is used because it moves between solid and liquid state easily, whilst retaining a 'pliable' solidity at room temperature. I use a 4 part paraffin wax to 1 part beeswax mixture, in the form of small easy melt pellets. These are visible on the un-melted surface of the wax bath below.

The wax potting process;

When building single coil guitar pickups of a higher resistance (thus more windings), the key stage is deep wax potting. The bath itself is a (relatively) low temperature unit, of the kind used for health / cosmetic wax procedures. The advantage is that the pickups can be left in for 20 + minutes, with little risk of any harm compared to higher temperature units. This ensures a thorough heat penetration throughout.

A wooden jig suspends 3 pickups at a time (i.e. a Stratocaster set) in the bath, thermostatically held at a consistent temperature. An insulating cloth covers the top, preventing the wax surface starting to 'film'. After about 10 minutes, a few gentle taps on each pickup with a wooden (chop!) stick knock out stubborn air bubbles to encourage a full wax filling.

After the timed immersion period, each pickup is withdrawn and a hot air gun used to blow off excess liquid wax. The pickups are then set to rest for a while on absorbent paper before the next manual steps.

After the timed immersion period, each pickup is withdrawn and a hot air gun used to blow off excess liquid wax. The pickups are then set to rest for a while on absorbent paper before the next manual steps.

Taping and testing;

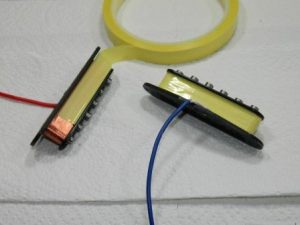

We visually inspect the pickups having cooled a little to ensure a full wax penetration and, if needed, that the wiring to the bobbin eyelets is not mechanically stressed.

With everything OK, the pickups are taped. I use high temperature 'transformer' tape, which, when applied tightly, bonds to the still warm wax and copper windings. This both seals the coil to prevent mechanical damage and squeezes the still soft wax. That maximises the coil mechanical stability. With the taping in place, another electrical resistance check is done. Because the coil is still warm, the reading is not accurate, but it will show that the coil and connections are all electrically intact.

Finishing and final testing;

With the pickups confirmed as electrically sound, a mechanical cleaning can occur. The wax process leaves a thin film over the entire surface of the pickups. While the idea is not to completely remove that, some cleaning makes cosmetic sense. A fine emery pad is used to remove wax from the exposed pieces themselves and gives a bright visual finish.

The rest of the resin is then lightly brushed with a scouring pad to remove any debris and unwanted wax deposits. Care must be taken at this stage not to brush across the small sections of exposed winding wire.

We find the connection of the hair thin windings to the bobbin eyelets is the most delicate part of a completed pickup. So 2 or 3 pellets of the same wax that was used in the bath is carefully melted with a small soldering iron tip over the 2 eyelet joints. Once dry, this small wax coating prevents accidental handing damage, but remains soft enough to allow for mechanical movement and temperature changes.

We find the connection of the hair thin windings to the bobbin eyelets is the most delicate part of a completed pickup. So 2 or 3 pellets of the same wax that was used in the bath is carefully melted with a small soldering iron tip over the 2 eyelet joints. Once dry, this small wax coating prevents accidental handing damage, but remains soft enough to allow for mechanical movement and temperature changes.

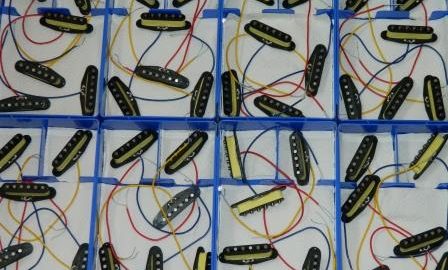

Preparing for 'Live' stock;

Building single coil guitar pickups like the Ironstone Hybrids in batches of around 20 pickup sets (60 pieces), gives about a day's worth of continuous flow wax potting.

Because the potting process significantly heats the copper wire coils, they are then left to 'rest' back to room temperature overnight before a final accurate measurement. That confirms they are within the stated 5 % +/- tolerance.We can then package up the fully prepared pickups, with associated screws set, tubing and information card. A new set of pickups is ready for Live stock!

So that is the full process for building single coil guitar pickups here at Ironstone, like the Hybrids. Different pickup styles have different operations (e.g. the Tele bridge pickup has a base plate hot glue process ). But the basics are the very much the same. I hope these 2 blogs give a good summary of what goes into the Ironstone Hybrid pickups.

And some related articles;

Single coil guitar pickups (Wikipedia)

StewMac on wax potting pickups

Building single coil pickups; Hybrids part 1